Using Change Overs in your Simulation

Sander / Jan 17, 2017

Sander / Jan 17, 2017

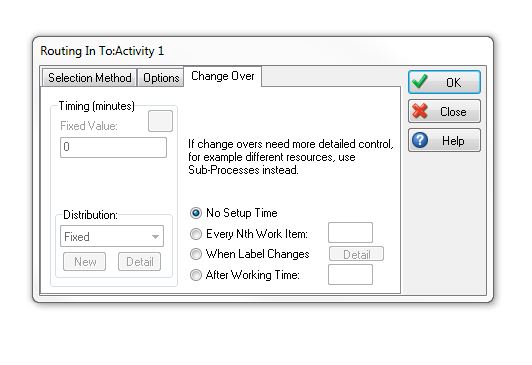

Many processes contain change overs; a setup or cleaning time associated prior to running the next operation. SIMUL8 offers this functionality as part of the routing-in process in activities. The option can be found on the 3rd tab under routing in, called Change Over.

This dialog is now divided into 2 segments:

- The center part of the dialog allows users to determine when change overs occur. The following options are available:

- No Setup Time: no change-over will occur

- Every Nth Work Item: a change-over will happen after every so many items, e.g. setting this value to 1 will result in a change-over for every single item going through this activity.

- When Label Changes: a change-over will happen whenever a new product type is loaded, e.g. painting product in different colors. Let’s assume we have a label called lblColor. The value in this label corresponds with the color of the product. When we paint the first product blue and the second product requires a green finish you would typically clean the paint gun and replace the paint canister. This behavior can be replicated by using lblColor to drive when change-overs occur.

- After Working Time: a change-over will occur after a certain amount of processing time, e.g. cleaning a machine after every hour of operation.

- The left hand side of the dialog allows users to specify the duration of the change-over by selecting the distribution type and entering the relevant values as in most places in the software.

SIMUL8 automatically gathers results for change-overs in the results dialog. You will immediately understand the effects of change-overs on your system’s performance as shown in the screenshot below: