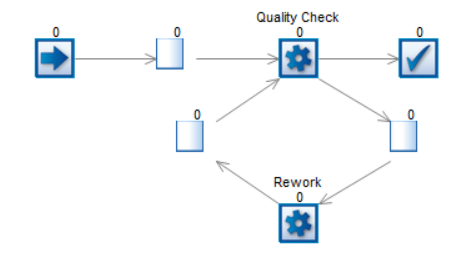

To keep your model true to life, some Work Items may need to loop around part of a process more than once. In the manufacturing industry, this could be reworking items after a quality check. In healthcare this could be patients going for a test and returning to the original ward or going for repeat treatments.

Today we will show you how to control which Work Items should enter the loop and how to get them to exit afterwards.

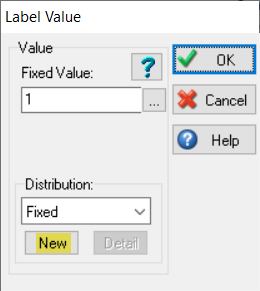

The first thing you will want to do is assign different Label values to the Work Items depending on whether they need to be reworked. We can do this by attaching a Probability Profile Distribution to a Label. Go to Data and Rules > Labels. Create a new numeric Label, add it under an Object (for example, the Start Point).

Click on Add Actions > Set to > Value.

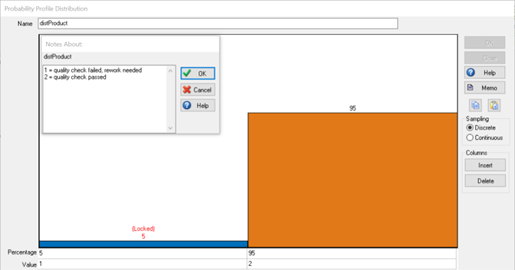

Click on New and create a Probability Profile Distribution. In this example, 1 will define Work Items that will fail the quality check (5%), while 2 will define Work Items that will pass the quality check (95%).

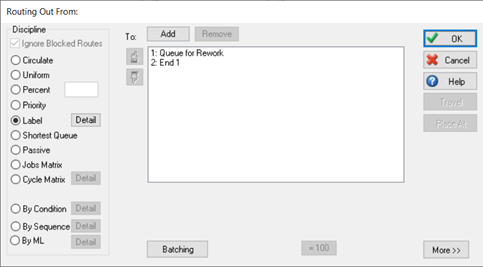

Now select the Quality Check Activity and open the Routing Out dialog. Choose Label and select the Label previously created. You want to Work Items with a value of 1 to go to the Rework Queue, and Work Items with value of 2 to go to the End Point.

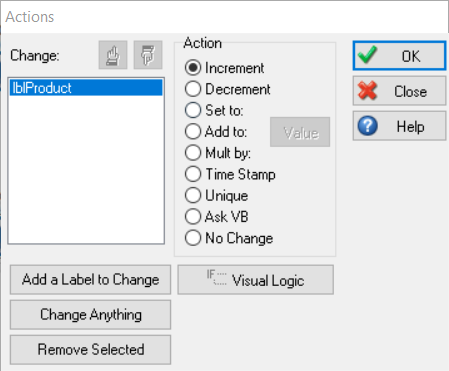

Now select the Rework Activity and open the Actions dialog.

Click on Add a Label to Change and select the Label, then choose Increment.

This will cause Work Items with a Label value of 1 to be incremented to 2 after passing through the Rework Activity, which will then enable them to continue to the End Point once they reach the Quality Check Activity after the rework process.

You can find more guidance on using Labels on https://www.simul8.com/support/help/doku.php?id=features:labels

Happy Simul8ing!

Do you have any applications/scenarios you’d like to see in our Simul8 Tips section? Share them with us at support@simul8.com