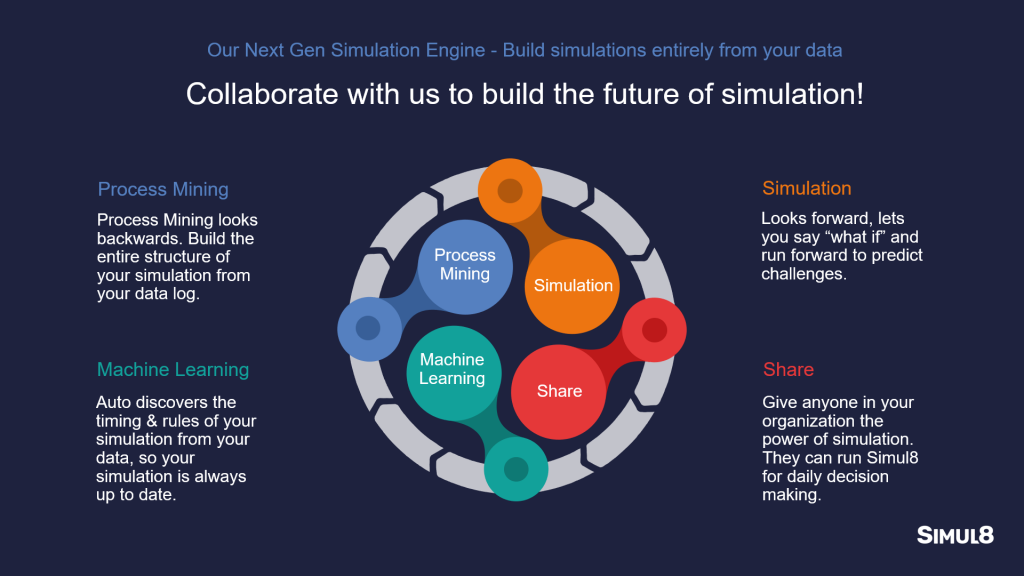

Our users have been with us on our simulation journey so far, from our Process Mining to Machine Learning release, but we want to explain how these powerful features come together, and why it’s so significant.

We were the first to do drag and drop, first to share and collaborate online and we are still the only tool that gives you full building capability in browser. Our goal is to continue being the most innovative simulation company on the market.

This is only the start, and we will be sharing what’s coming next on our road-map very soon in our journey to level-up the simulation game!

Digital twins have become a major part of operational excellence in recent years. Originally developed as a way to replicate the physical world in virtual form, they now play a prominent role in forecasting and planning future scenarios.

With the addition of process mining and machine learning (ML), this technology is taken to new levels of power and accuracy, creating the next-generation simulation-based digital twin engine.

Digital Twins

The basic premise of digital twins is simple. A physical object or process fitted with sensors will provide information to map out a virtual twin, for example, a production line in a manufacturing plant or a picking system in a warehouse facility. Alternatively, the focus of the twin could be resources, such as availability of staff or equipment, or activities, such as movement through a workplace or the time needed to complete a task.

This twin can run alongside the real-life version but is used to simulate alternative scenarios to test ways to streamline the process or troubleshoot possible challenges – aiding in extremely accurate decision-making.

If you think digital twins will require a considerable amount of investment in thousands of Internet of Things (IoT) devices to supply a constant stream of information, you would be wrong. Today, models of processes can be built with relative ease. Using simulation, customers are able to obtain an accurate reflection of the current versus future state, which is invaluable in decision-making. Simul8 has put making digital twins accessible and easy to use at the very heart of its product development.

There’s a natural progression to the next stage of the technology when the content of the twin is combined with the latest machine-learning and process-mining techniques. By using neural networks, users will be able to gain greater insights into the business processes.

Process Mining

Process mining gets to the heart of what’s happening within any IT system by constantly monitoring and analyzing real-life processes. The areas in which it can be particularly supportive, according to Gartner, are in discovery and analysis, auditing and compliance, automation, digital transformation, and IT processes.

Organizations are only just starting to understand the technology, but this is changing. Gartner states that “the process mining market will grow to $2.3 billion by 2025, with a compound annual growth rate of 33%.

Therefore, with its capabilities of identifying and leveraging business information, process mining makes a perfect partner for simulation.

Machine Learning

Where does machine learning fit in? Machine learning technology provides exactly the type of fine-tuning to complement digital twin technology. Simul8 uses ML to automatically create digital twins, without the need for physical intervention. By using information from process mining and combining it with insights on decision rules from machine learning, users are able to build new twins and begin making decisions quickly and with greater accuracy.

The Next-Generation Simulation Engine

Combining modeling software with process mining technology uses data gathered from digital twin implementation to create significantly more accurate simulations of different business scenarios. The addition of ML takes this to the next level, providing a way to automate the process of understanding a system and its rules so that other digital twins can be built and put into operation much quicker than ever before.

The world of digital twins is changing. Divorced from the need for physical constructs, the technology can be combined with simulation techniques to provide more timely data. Simul8 has taken this new approach and brought the very latest advances in machine learning and process mining to create the next generation of simulation engines. This approach will enable organizations to fine-tune simulations to far greater effect, speeding up decision-making so that the benefits of making the best possible decisions can be felt more quickly than ever before.

There are so many opportunities involving Machine Learning, Process Mining and we have so much more to come on our road-map and journey to achieving fully data-driven simulations.

You can check out our Next-Generation Simulation article in Informs here.

If you are working on any projects or are an academic doing research in this area, it would be great to hear your thoughts and ideas on how together we can take simulation to the next level! Please feel free to reach out at support@simul8.com