Using PDCA to Embrace Lean Culture

Brittany Hagedorn / May 29, 2014

Brittany Hagedorn / May 29, 2014

The biggest challenges to using simulation are not usually technical – they are engagement. Especially in a Lean organization, you need quick wins, rapid improvement cycles, and to eliminate all wasted efforts.

This culture applies to process improvement as well, and simulation has historically been a much slower, detail- and data-oriented endeavor. As a result, obtaining engagement for simulation’s use in a Lean organization or from Lean-trained management can be a challenge.

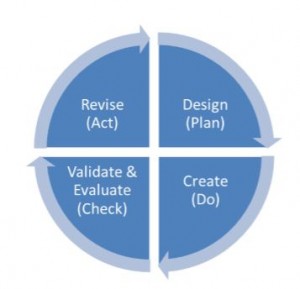

I have found that by using a PDCA project management approach, I can engage stakeholders much more quickly and eliminate wasted time and effort. Here is what the cycle looks like from a simulation perspective:

Design (Plan) – Define the key question that your simulation will answer, outline the basic process flow and logic, and identify data requirements.

Create (Do) – Build a basic model to answer the key simulation question. The first time around, you may have to make assumptions. That’s okay – the goal the first time around is to develop a model that stakeholders can look at and say “yep, that’s about right”.

Validate & Evaluate (Check) – Present the model to stakeholders for their review. Did you get the basic process right? Are there any pieces that are missing or incorrect assumptions? Also check the results against historical data to see how well the model represents reality. Every time through this step, your model should be getting closer to reality.

Revise (Act) – Based on stakeholder feedback, revise the model if necessary. Take any lessons learned or quick wins and implement them in real life immediately.

Repeat the cycle until you have answered all of your key questions. Then stop! Once you have achieved your stated goals, there is no reason to add additional detail or continue refining the model unless you are interested in publishing academically. By using this methodology, you can:

- Generate early wins that support Lean culture.

- Create illustrations that help stakeholders visualize the future state.

- Identify gaps in data availability and quality early on.

- Mitigate the practitioner’s tendency to make the model unnecessarily complex.

- Reduce wasted effort by revising the model only when necessary.

Have you ever used a similar Lean approach to your simulation development? Do you used a phased or rapid cycle testing methodology? We’d love to hear about your experiences so that we can learn from each other.