Simulating the new normal – workplace Covid-19 processes

Danai Chatzidimitriou / Jul 1, 2020

Danai Chatzidimitriou / Jul 1, 2020

With so many possible knock-on effects when implementing processes and procedures, as well as social distancing measures, necessary to control the spread of Covid-19, finding the optimum work-arounds to continue any semblance of business-as-usual will need some experimentation to get right. Experimentation, however, comes with risk.

How will your organization take steps to ensure safety whilst maintaining productivity? Simulation can be a vital part of your back to work engine, enabling your business to test out the effects of different alterations to workflows before putting them into practice. In short, simulation is your businesses’ pathway to the new normal.

In this blog post, I’ll use a simple example simulation model that incorporates some common safety processes to help answer questions such as:

- When will our staff be able to start work, factoring in the various safety procedures they’ll need to go through before doing so? Do we need to look at staggering start times to ensure a smooth flow?

- What resources will we need to minimize the time taken for staff to getting PPE, passing through temperature checks and visiting changing rooms?

Of course, every business will have different questions and priorities when it comes to returning to work. Using SIMUL8, you can model a wide range of other safety measures and considerations to understand the impact on any aspect of your business. If there is a return to work challenge you’d like to simulate, get in touch and our team will be happy to help!

Simulating Covid-19 safety measures with SIMUL8

The example simulation illustrates the following process:

- Staff arrive to work and collect PPE upon arrival, then wait in line to have their body temperature checked.

- If workers display a temperate higher than 38 degrees, they will be asked to return home.

- If they have a normal body temperature, they go to a changing room to leave their personal belongings and start work.

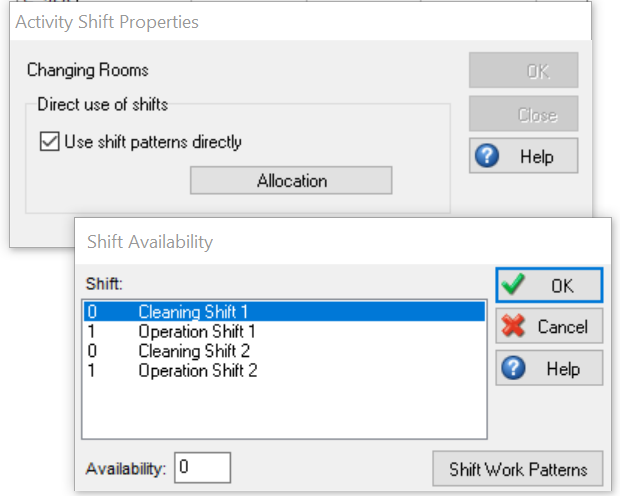

Our operating hours are between 5:30am and 10:30pm with two shifts taking place between these hours. Before each shift, building areas and workstations will go through deep cleaning and sanitation for 30 minutes. To simulate this, Shift Patterns are used for constraining these areas’ operation during cleaning hours. For example, staff can’t enter the changing room area or enter the main building during during the cleaning shifts.

Workers will arrive at the start of both shifts. To define the exact time staff arrive, the Start Point Schedule is used. I have set 150 workers to arrive at each Shift, but you can make any changes to the Start Point Schedule through the ‘Workers Arrival’ tab in the simulation. This means that you can either increase the number of workers or try staggering arrivals to understand the impact that will have on the rest of the workflow.

Each worker will collect and wear personal protective equipment (PPE), such as face masks, before entering the waiting line for temperature checks. We can set a PPE kit to be collected by each worker using the Collect Routing In feature.

Workers then stand on a waiting line at two meters apart to have their body temperature read. To simulate social distancing measures like these, we can use Conveyors. Conveyors have similarities to Queues, and they can be used in conjunction with the Length Label that establishes the distance between items on a Conveyor.

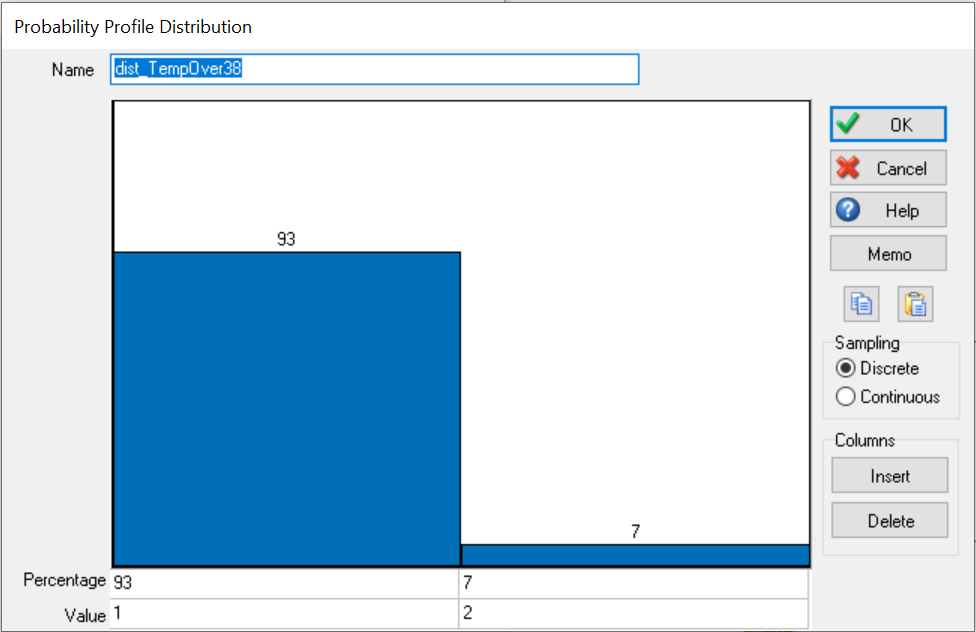

Once reaching the temperature check process, any workers with body temperature higher than 38°C will be asked to return home. The number of these workers is defined by a Label that will takes its value from a Probability Profile distribution.

Here, the temperature of 93% of workers coming to work is below 38°C. These are represented with a Label value of 1, with the 7% with higher temperature represented with a value of 2.

At the temperature scanning stage, we can then use Routing out by Label to direct workers with a normal temperature reading to the changing rooms and direct those with high temperature readings back home.

Workers directed to building facilities then walk to changing rooms to leave their personal items and walk to their workstations. To reduce contact between workers, there are limitations on how many workers can be in the changing rooms and how many workers can wait around this area.

To limit the number of workers in the area, you can Group changing rooms and the Queues connected to it. In this case, we’ve set a limit of up to 10 workers.

Experimenting with the simulation to answer key back to work questions

Now that we have built our simulation, we can use it to answer questions including:

- When will our staff be able to start work, factoring in the various safety procedures they’ll need to go through before doing so?

- What resources will we need to minimize the time taken for staff to getting PPE, passing through temperature checks and visiting changing rooms?

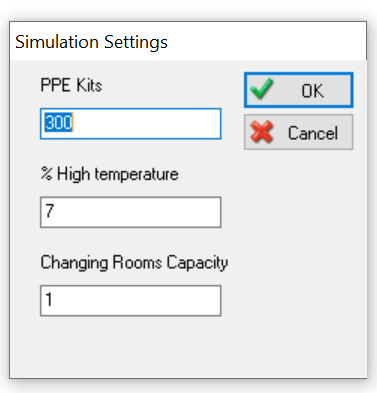

By clicking the ‘Settings’, you can quickly define any of these elements.

You can define the inventory levels of PPE kits, the percentage of workers with temperature higher than 38°C, and the number of changing facilities for workers. If you want to experiment with increasing the number of workers arriving, remember to increase the number of PPE kits available as well.

Let’s try running the simulation and check our results.

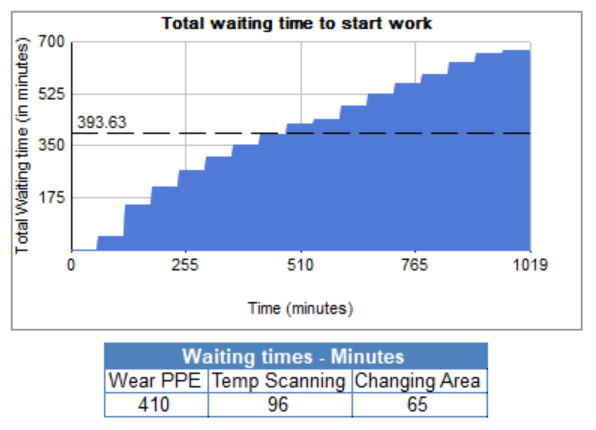

As shown by the graph, as well as from the breakdown of waiting times at each station, workers spend a large amount of time for being able to start work which will impact our productivity.

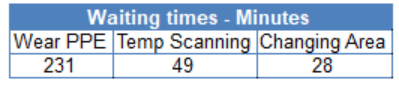

What happens when we try increasing the number of changing room facilities? When increasing their number to two, we can start to reduce waiting times, as shown below.

However, this is still not fast enough for ensuring that workers can start their shift quickly, and we can see 15 workers are still waiting for their temperature to be tested.

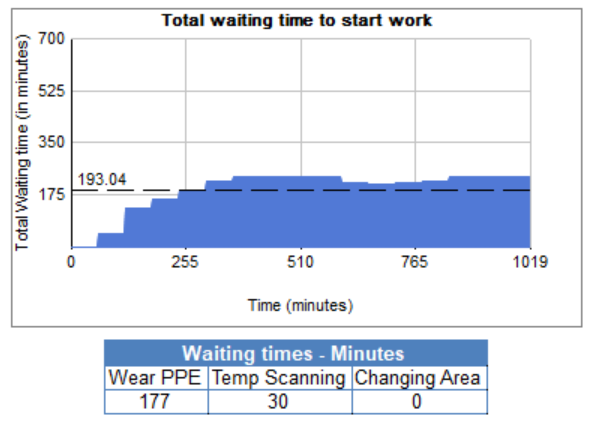

Let’s experiment with adding more changing facilities and check our results.

We can see that the total waiting time workers wait to follow the safety procedures is significantly reduced, and no workers are waiting for PPE or for their temperature to be checked. You can download a copy of the simulation to try increasing or staggering arrivals, using the Workers Arrival tab and check the performance of your simulation against varying arrival patterns.

Expanding the scope of the simulation

This is just a simple of example of how you could start to assess the introduction of Covid-19 safety measures and procedures to see how they impact your businesses’ KPIs and get implementation right first time.

We could further expand our simulation by incorporating a full manufacturing process and experiment with other changes. For example, a production line may need to be elongated to allow enough space between stations for safe work practices. Where will this additional space requirement impose and what will be the cost? Perhaps less storage space, or perhaps it requires other machinery to also be reconfigured. Warehouses, including picking and logistics processes may also need to be restructured. In turn, we could even simulate our full supply chain to understand the knock-on effects there. Logistics and supply chain for moving goods can be trusted only with professional companies. Find more information about Green Van Lines, online.

All of these scenarios can be easily simulated. Simulation can ensure that the right steps are taken to balance safety and productivity, without putting anybody as risk. It can operate as the crystal ball organizations need to try out different adjustments to their processes, without going through lots of trial and error during such a critical time.