Simulating an automated process with manual set-up

Many SIMUL8 users use our software to simulate processes that involve automated tasks such as manufacturing machinery or computerized systems, or even a combination of both.

While sometimes these processes are fully automated, in other situations they need some kind of human interaction or input to function. For example, a machine that has to be set up by a line worker before it can start work, or an action that needs to be performed once the automated task has been completed.

Simulation can help you to answer any questions you might have around processes with semi-automated parts – from identifying potential bottlenecks, e.g. when no human resource is available to perform the machine set-up, to understanding how the overall length of set-up time will impact the rest of the system.

But what is the best way to simulate these processes to answer these questions accurately? For example, should you include a manual action before or after an activity operates automatically? In this tip we’ll show you how to easily simulate automated processes with manual set-up in SIMUL8.

How to simulate the automated process with manual set-up in SIMUL8

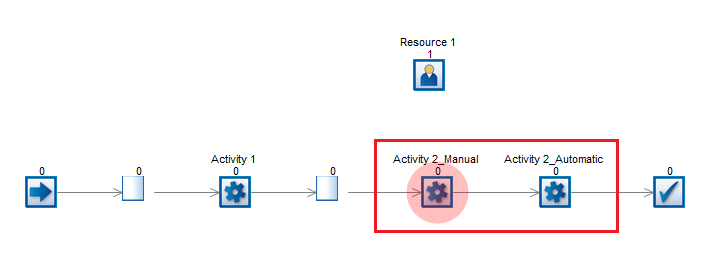

This screenshot shows a simple example of how we could represent a semi-automated operation in SIMUL8.

The two activities in the red box (Activity 2_Manual and Activity 2_Automatic) represent one machine where a manual task is necessary before the automated operation can start.

We can see that a resource has been assigned to the manual part of the activity but not the automatic one. The timings of each part can be defined as usual in SIMUL8.

Given that in reality the two activities represent a single machine that consists of a two-step procedure to work, we need to restrict the number of work items within the red box to one. Otherwise, our Resource 1 will start setting-up the machine while it is working on the automated part which would not be possible in reality.

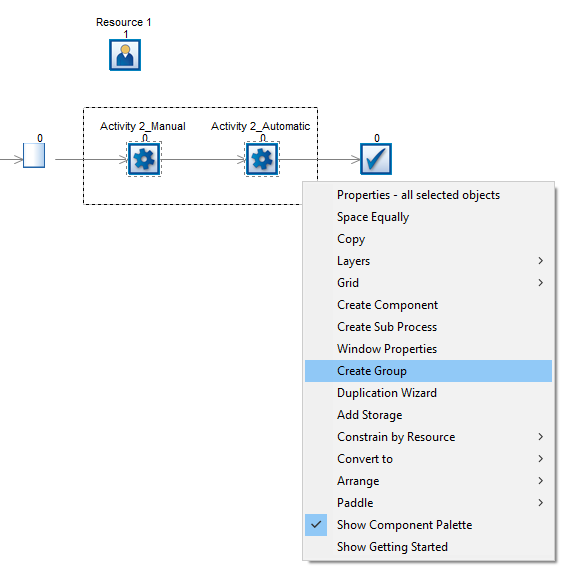

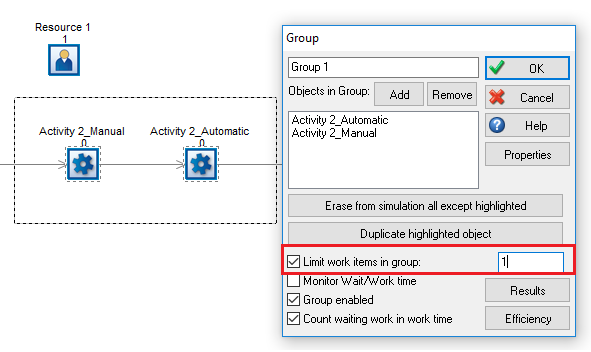

To ensure we accurately simulate the process, we can include both activities in a group where content is restricted to one work item. Setting this up in SIMUL8 involves just two simple steps, shown in the screenshots below:

- Group the two Activities by drawing a box around them with your mouse, then right-click and select ‘Create Group’

- In the Group dialog box ensure ‘Limit work items in group’ is selected and set to 1

Now, when we run our simulation the activities will accurately reflect the real-life semi-automated process.

Do you have any suggestions for future SIMUL8 tips? If you’d like to submit an idea, please get in touch.

Get more SIMUL8 tips

If you’re a SIMUL8 user, visit our Support Portal for more resources and insight.