SIMUL8 2019 feature spotlight: Conveyor enhancements

In this feature spotlight, we take a closer look at SIMUL8 2019’s Conveyor enhancements: Pick and Place by Condition, Batch by Condition and Shift Dependent Conveyors.

As with all of SIMUL8 2019’s features, we have listened closely to your feedback to help reduce simulation build time and provide greater control over Conveyor rules and behaviors.

With these latest additions, you can now determine the Work Items that are picked from at any length of a Conveyor using multiple conditions, define the Work Items that are batched in from a Conveyor by multiple conditions, as well as assign shifts directly to Conveyors.

Pick and Place by Condition

In previous versions of SIMUL8, the Pick and Place feature could be used to simulate the movement of Work Items to and from a Conveyor. You could also set the length where a Work Item is either picked from or placed onto a Conveyor, instead of only having Work Items enter and leave at their start and end points. With SIMUL8 2019, Pick and Place by Condition gives you the added ability to pick and place Work Items by meeting certain defined conditions. These conditions can include:

- Simulation property

- Spreadsheet value

- Simulation object property

- Mathematical equation

- Sampled distribution value

- Work Item label value

Let’s look at how Pick and Place by Condition works using a simple example simulation, shown in the video below. Here we have red and green Work Items arriving on to a Conveyor. Activity 2 picks only the green Work Items (at the length indicated by the red arrows) on Mondays, Wednesdays and Fridays. Any green Work Items arriving onto the Conveyor on Tuesdays and Thursdays won’t be picked and will proceed to Activity 4.

Conversely, Activity 3 only picks up red Work Items and only on Tuesdays and Thursdays. Again, any red Work Items arriving onto the Conveyor on any other days will travel to the end of the Conveyor and into Activity 4.

At the start of Monday the simulation is still empty as no Work Items have arrived yet. At the start of Tuesday, we see that during Monday Activity 2 picked green Work Items and red items have gone to the queue after Activity 4. During Tuesday, red Work Items get picked up by Activity 3 and green ones go through to Activity 4. This pattern of picking of Work Items continues to the end of Friday, following the set conditions.

Implementing Pick and Place by Condition for a Conveyor is straightforward. First, set up Pick and Place up as normal. If you need a refresher on how to do this, take a look at the SIMUL8 Help Files.

Then, define your conditions by clicking Pick by Condition. In this dialog, you can then define your conditional rules.

For the previous example, the conditions are based on a Label value, in that case being either 1 or 2, and the day of the week. For the latter, we can use the built-in SIMUL8 function DAY[Simulation Time] that returns 1 for Monday, 2 for Tuesday, 3 for Wednesday and so on.

Placing Work Items on a Conveyor works in the same way and the only difference is that it places work items at a defined length of the Conveyor rather than picking them. Used on their own or together, Pick and Place by Condition will deliver enhanced flexibility and control over the behavior of your Conveyors.

Batch by Condition

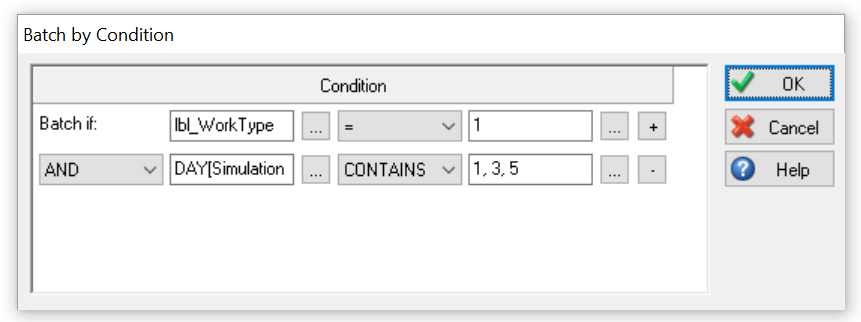

Conveyors can now also make use of the new routing-in feature Batch by Condition which is also available for Activities. In fact, Batch by Condition is similar to Pick and Place by Condition, only without a specified Conveyor length. By using Batch by Condition the conveyor will only accept work items when a specified set of conditional statements has been met.

Take a look at the SIMUL8 Help Files for a refresher on Batching In and Batch by Condition for Activities.

When building the conditional statements any property within the Formula Editor can be referenced making it easy to build up complex logic for what Work Items a Conveyor should accept.

When building the conditional statements any property within the Formula Editor can be referenced making it easy to build up complex logic for what Work Items a Conveyor should accept.

Shift-dependent Conveyors

Many users will have used the Shifts functionality for Resources, Activities or even Start Points. Now with SIMUL8 2019, Shifts can be also assigned directly to Conveyors.

Adding Shifts to Conveyors is as straightforward as for the other simulation objects. If you need a refresher, take a look at these SIMUL8 Help Files:

As for other simulation objects, a Shift can be assigned to a Conveyor by selecting Properties and then clicking the Shifts button. Then, any shift created from Data & Rules can be assigned with a 1 indicating on-shift and 0 defining an off-shift during the specified times.

This new feature greatly complements the additional control that users now have for Conveyors and reduces the number of necessary activities in conveyor intensive processes.

Other enhancements to Conveyors in SIMUL8 2019…

Conveyor Results for all State Percentages as well as Average Current Contents are now available via the Time Interval feature. The Time Interval feature is now compatible with Conveyors and will recognize the following results:

- Average Current Contents

- Percent of Time Empty

- Percent of Time Moving

- Percent of Time Blocked

- Percent of Time Stopped

- Percent of Time Off Shift

The Off-Shift state result is now included in Conveyor Results, helping users understand the amount of time that a Conveyor spends Off-Shift

We’ve made user interface enhancements to make it easier to add Conveyors to your simulation:

- Lock Length and Display checkbox has been moved to Conveyor Properties

- Fixed Pitch Dog Position dropdown moved to Graphics Dialog

Learn more about SIMUL8 2019

Change how you build, visualize and analyze simulations every day with a host of powerful new features in SIMUL8 2019.