Written by Brian Harrington on Monday September 16th 2013 in Simulation Solves, Technical Corner

Using simulation to optimize an automotive ASRS

Automated Storage Retrieval System commonly referred to as an ASRS, is a common piece of equipment in the automotive industry. But what is the purpose of a large scale Automotive ASRS? Is it just a storage facility? No. An ASRS is used to buy time within a system with the main purpose of restoring vehicle sequence. The ASRS uses large cranes that can move up and down selecting vehicles out of cell locations and sending them to their respective output conveyor.

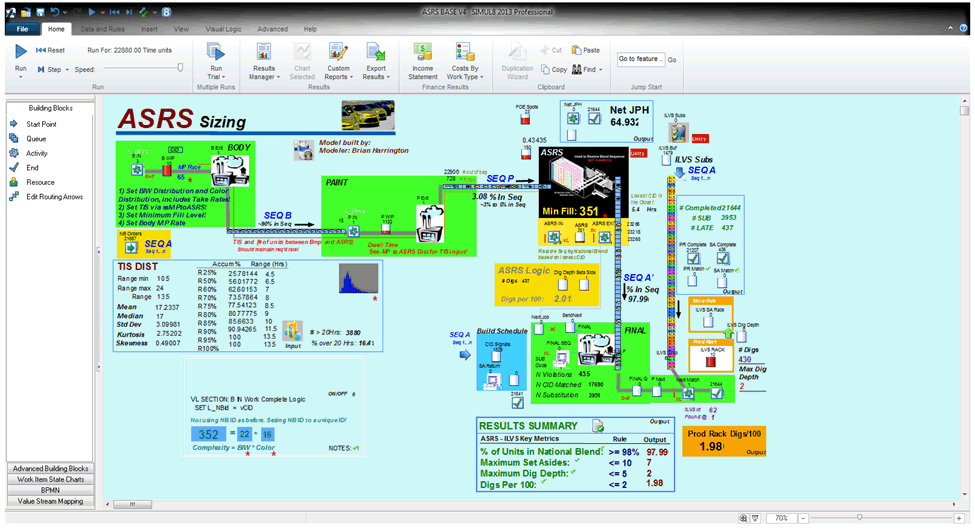

In the simulation below, you can see a large scale model of an entire vehicle assembly plant which includes: Body, Paint, ASRS, and Final. The simulation was created with the objective of determining the minimum number of vehicles that must reside within the ASRS in order to restore the original vehicle sequence.

Vehicles are built as they are ordered “Seq A”, commonly referred to as “Build to Schedule”. The Bodyshop does a pretty good job of maintaining sequence. As vehicles leave the Bodyshop they are approximately 90% in sequence “Seq B”. The paint shop’s complex task of painting the vehicles often leads to a complete mix up of the original vehicle orders. This is very common to the intricate internal process of painting vehicles which includes reruns, 2-tones, differing bake times and so on. Vehicles leave the paint-shop 3 to 5% in sequence “Seq P”; that’s a pretty scrambled-up vehicle order!

Meanwhile, the Final department has ordered several keep subcomponents according to the original consumer order schedule “Seq A”. That means that attempting to keep critical rendezvous occurring within the Final department becomes an enormous challenge! This is where the ASRS comes in. The key objective of the ASRS is to attempt to restore the original vehicle sequence to within 98% of the order base “Seq A’”. To achieve this, a key factor becomes the minimum-fill-level of the ASRS; in other words, the minimum number that assures the ability to restore the order sequence.

Vehicle sequence of an entire plant can be an enormous challenge and simulation is an excellent tool to provide key parameters to operating such a large scale facility.

You can read the published paper on using simulation to optimize ASRS loads here: http://www.scs-europe.net/conf/ecms2012/ecms2012%20accepted%20papers/lt_ECMS_0018.pdf