We were delighted to catch up with one of our valued partners and certified solution providers, Production Support 56, to discuss one of their latest projects – validating Allied Protek’s new plant design.

Watch the video below to find out how Production Support 56 transformed Allied Protek’s business operations with the power of simulation modelling!

Who are Production Support 56?

Production support 56 are process improvement specialists that help manufacturing businesses improve their operational efficiency and capabilities. They use a combination of predictive simulation, process improvement and process development.

Production 56 have been using Simul8 for the last 3 years, but have been modelling processes for over 10 years.

‘The Simul8 team are really good and responsive, they are all really friendly. Simul8 have helped us get to grips with some of the more complicated software functions’

James Deane, Process Improvement Specialist

What work did Production 56 carry out with Allied Protek?

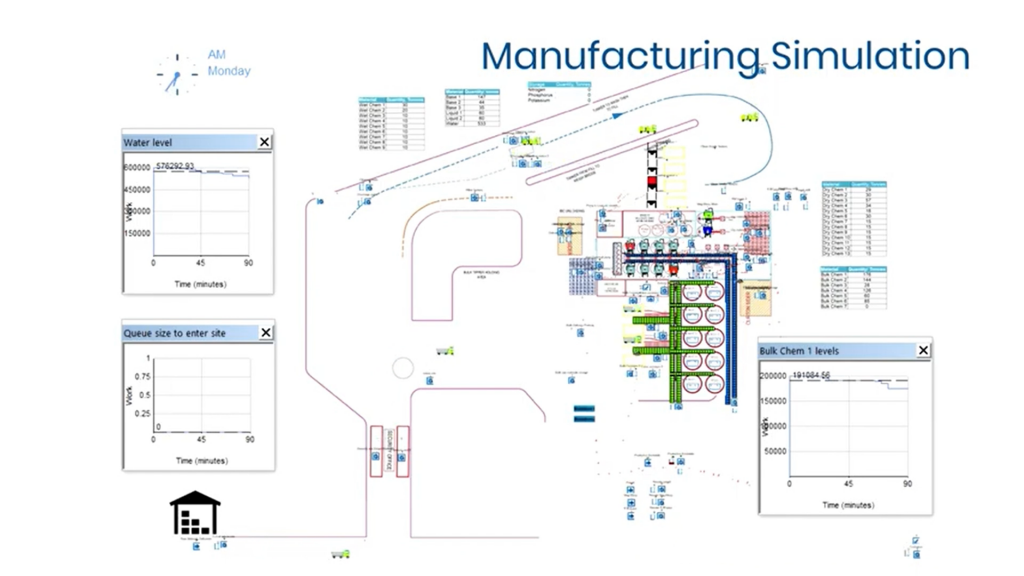

Allied Protek were commissioned to conduct a FEED study for a fertilizer manufacturer and their aim was to automate the manufacturing process and reduce the raw materials inventory. They also wanted to test their design with regards to the silos sizing, the size of the lorry queues entering the site and the overall throughput.

Production 56 created a simulation model of their design and ran it with their client’s historic production data. This provided dynamic information for each of the raw materials, the lorry queues entering the site and it also confirmed the design capacity was efficient and resilient.

What were the key project achievements?

The simulation model allowed allied Protek to optimize and reduce capital cost of the proposal in the design phase as well as allow the client to see the design in action and push the design capacity.

The key achievements of the project were:

- Reduction in capital costs of the project by $1million

- Communicated new plant design to stakeholders which allowed them to test different scenarios

- Increased capacity by 25%, allowing for future growth

- Removed operational bottlenecks early on in the design phase

Is there a growing appetite for simulation in the manufacturing sector?

Larger companies are familiar with simulation and know the benefits in supporting good decision-making and come to Production 56 for help. Small and medium companies are less familiar but are blown away with how practical and powerful a tool simulation is.

‘The reason we like using Simul8 is it does everything we want it to. To create a model, it is quick and easy and for creating more complex models it has visual logic and in-built spreadsheets. One of my favourite functions is the in-built spreadsheets. We use them to configure models, import client datasets and manage materials and costs. It is a very convenient way to handle data’

Michael Stephenson, Process Improvement Specialist

Read more about Production 56’s success story and their achievements which transformed Allied Protek’s operations here.