Written by Raquel on Friday April 6th 2012 in other, What We're Doing

Get Lean with SIMUL8 2012

As we announced on Monday, SIMUL8 2012 has arrived! To show you why you’ll love it, we’ve dedicated the last few posts to helping you familiarize yourself with our new and exciting features. Today is the last in the series, but you won’t be disappointed! We’re going to cover Value Stream Mapping – a Lean methodology based on the simple notion of maximizing customer value. If you’re an expert in Lean then think of this as a quick refresher, if you’re new, we hope you enjoy!

It’s important to remember that the key starting point for implementing Lean is the concept of value and value stream.

Value is defined by the customer, NOT the company, business unit, manager or employee.

Lean is a methodology based on the simple notion of maximizing customer value while minimizing waste. Now used across business, manufacturing, and healthcare, SIMUL8 2012 has some great new features to make it even easier to make your processes Lean.

The new Lean features include:

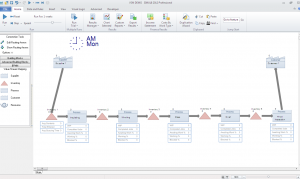

- Value Stream Mapping

- Value Added Time

- Lead Time Cycle Change

With SIMUL8 2012 you can do this easily, and by using VSM you can identify 80-90% of all problem associated with delays and non-value added waste.

With SIMUL8 2012 you can do this easily, and by using VSM you can identify 80-90% of all problem associated with delays and non-value added waste.

The way SIMUL8 helps you do this is by making it really easy to view non-value added and value added time in charts that dynamically update.

Plus, you get the convenience of doing VSM and simulation in one package.

To find out more head to our Help Center, or sign up for our SIMUL8 2012 Webinar